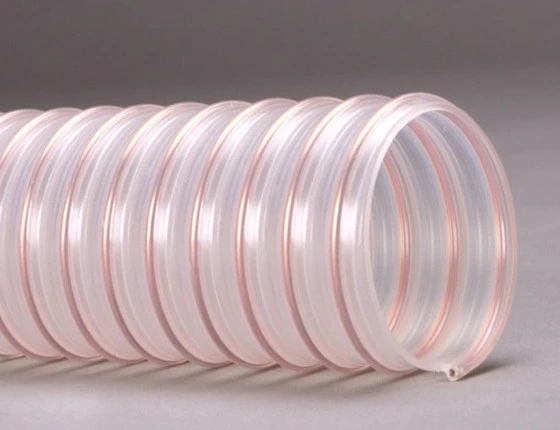

FLEXADUX HT PU

POLYURETHANE HOSE FOR HIGH TEMPERATURE APPLICATIONS

HIGH TEMPERATURE PU HOSE - 145°C

Structure

Polyester- Polyurethane, translucent reinforced with copper coated spring steel wire.

Characteristics

Resistant to hydrolysis and microbes, good flexibility, smooth bore, Food Grade

Available Wall thickness: 0.7 / 1 / 1.4 mm

Applications

Wall Thick : 0.7 mm

Suction and transport of light weight materials (dusts, splinters and fibres) in food, paper and textile industry for high temperature applications

Wall Thick : 1 / 1.4 mm

Suction and conveying of abrasive particles or granules for high temperature applications

Temperature Range

-40℃ to +145℃ (short-term 165° C)

Standard Packing

10 / 15 Meters

Technical Data

Wall thick 0.7 mm

| I.D. Ø (mm) | Weight (kg/m) | Wall Thickness (mm) | Bending Radius (mm) | Working Pressure (bar) | Vacuum Pressure (bar) |

|---|---|---|---|---|---|

| 25 | 0.28 | 0.7 | 25 | 1.5 | 0.43 |

| 30 | 0.33 | 0.7 | 30 | 1.39 | 0.32 |

| 40 | 0.43 | 0.7 | 40 | 1.23 | 0.32 |

| 50 | 0.51 | 0.7 | 50 | 1.07 | 0.27 |

| 60 | 0.6 | 0.7 | 60 | 1.07 | 0.27 |

| 70 | 0.69 | 0.7 | 70 | 1.07 | 0.22 |

| 75 | 0.74 | 0.7 | 75 | 1.07 | 0.22 |

| 80 | 0.79 | 0.7 | 80 | 0.86 | 0.21 |

| 90 | 0.88 | 0.7 | 90 | 0.86 | 0.19 |

| 100 | 1.04 | 0.7 | 100 | 0.64 | 0.19 |

| 110 | 1.14 | 0.7 | 110 | 0.64 | 0.16 |

| 120 | 1.16 | 0.7 | 120 | 0.54 | 0.16 |

| 125 | 1.2 | 0.7 | 125 | 0.43 | 0.11 |

| 140 | 1.34 | 0.7 | 140 | 0.43 | 0.11 |

| 150 | 1.43 | 0.7 | 150 | 0.41 | 0.11 |

| 160 | 1.52 | 0.7 | 160 | 0.37 | 0.09 |

| 175 | 1.66 | 0.7 | 175 | 0.33 | 0.08 |

| 180 | 1.76 | 0.7 | 180 | 0.32 | 0.08 |

| 200 | 2 | 0.7 | 200 | 0.27 | 0.05 |

| 225 | 2.24 | 0.7 | 225 | 0.21 | 0.04 |

| 250 | 2.48 | 0.7 | 250 | 0.21 | 0.04 |

| 300 | 3.66 | 0.7 | 300 | 0.16 | 0.02 |

| 350 | 4.25 | 0.7 | 350 | 0.11 | 0.01 |

| 400 | 4.84 | 0.7 | 400 | 0.09 | 0.01 |

| 450 | 5.43 | 0.7 | 450 | 0.07 | 0.01 |

| 500 | 6.02 | 0.7 | 500 | 0.05 | 0.01 |

Wall thick 1 mm

| I.D. Ø (mm) | Weight (kg/m) | Wall Thickness (mm) | Bending Radius (mm) | Working Pressure (bar) | Vacuum Pressure (bar) |

|---|---|---|---|---|---|

| 25 | 0.19 | 1 | 33 | 1.45 | 0.55 |

| 30 | 0.25 | 1 | 39 | 1.45 | 0.55 |

| 35 | 0.3 | 1 | 46 | 1.25 | 0.45 |

| 38 | 0.33 | 1 | 49 | 1.25 | 0.45 |

| 40 | 0.35 | 1 | 52 | 1.25 | 0.45 |

| 50 | 0.41 | 1 | 65 | 1.2 | 0.4 |

| 60 | 0.47 | 1 | 78 | 1.15 | 0.35 |

| 75 | 0.61 | 1 | 98 | 1.05 | 0.3 |

| 80 | 0.65 | 1 | 104 | 1.05 | 0.25 |

| 90 | 0.8 | 1 | 117 | 0.85 | 0.25 |

| 100 | 0.95 | 1 | 130 | 0.7 | 0.23 |

| 110 | 1.02 | 1 | 143 | 0.65 | 0.2 |

| 120 | 1.08 | 1 | 156 | 0.65 | 0.2 |

| 125 | 1.13 | 1 | 163 | 0.55 | 0.2 |

| 140 | 1.18 | 1 | 182 | 0.55 | 0.15 |

| 150 | 1.25 | 1 | 195 | 0.45 | 0.15 |

| 160 | 1.34 | 1 | 208 | 0.4 | 0.15 |

| 180 | 1.68 | 1 | 234 | 0.35 | 0.12 |

| 200 | 1.87 | 1 | 260 | 0.3 | 0.1 |

| 225 | 2.11 | 1 | 293 | 0.25 | 0.09 |

| 250 | 2.35 | 1 | 325 | 0.25 | 0.09 |

| 300 | 3.08 | 1 | 390 | 0.2 | 0.07 |

| 350 | 3.75 | 1 | 455 | 0.18 | 0.06 |

| 400 | 4.24 | 1 | 520 | 0.15 | 0.06 |

| 450 | 5.42 | 1 | 585 | 0.15 | 0.06 |

Wall thick 1.4 mm

| I.D. Ø (mm) | Weight (kg/m) | Wall Thickness (mm) | Bending Radius (mm) | Working Pressure (bar) | Vacuum Pressure (bar) |

|---|---|---|---|---|---|

| 38 | 0.44 | 1.4 | 70 | 2.9 | 0.9 |

| 40 | 0.47 | 1.4 | 70 | 2.8 | 0.9 |

| 50 | 0.61 | 1.4 | 90 | 2.8 | 0.9 |

| 55 | 0.67 | 1.4 | 100 | 2.65 | 0.9 |

| 60 | 0.73 | 1.4 | 110 | 2.5 | 0.8 |

| 63 | 0.76 | 1.4 | 120 | 2.4 | 0.8 |

| 70 | 0.84 | 1.4 | 130 | 2.1 | 0.7 |

| 76 | 0.9 | 1.4 | 140 | 2 | 0.6 |

| 80 | 0.95 | 1.4 | 150 | 2 | 0.6 |

| 100 | 1.28 | 1.4 | 185 | 1.6 | 0.5 |

| 125 | 1.59 | 1.4 | 230 | 1.15 | 0.4 |

| 150 | 2.31 | 1.4 | 285 | 0.9 | 0.3 |

| 200 | 3.2 | 1.4 | 375 | 0.7 | 0.2 |